Commercial Duct

At Air & Electrical Services, we know not all duct-work is the same. The best duct system is designed specifically for you application. For information on the different types of duct-work system, see below.

Metal Duct Systems

Fiberglass duct-work cannot handle the higher pressure and larger size requirements of commercial many applications. That’s where metal duct comes in. Metal duct with duct-wrap is a type of duct-work that is made of metal and then wrapped with insulation.

Benefits of using metal duct with duct-wrap:

- Improved energy efficiency with insulation options

- Reduced noise

- It excels in durability

- It provides superior air flow, due to their smooth interior walls that reduce turbulence and air resistance

- It is easy to clean

- It has the least probability of mold or any other biological growth due to its non-porous nature

- Longer lifespan than fiberglass duct

Spiral Duct Systems

Spiral duct-work is a type of rigid duct-work that is made by winding a sheet of metal into a spiral shape and is found commonly in buildings with open ceilings. It is most commonly made of galvanized steel, but it can also be made of stainless steel, aluminum, or copper. Spiral duct-work is a versatile material that can be used for a variety of applications, including:

- Heating and cooling systems

- Ventilation systems

- Dust collection systems

- Industrial applications

Spiral duct-work is available in a variety of sizes and shapes to meet the specific needs of each application. It is also relatively easy to install and maintain.

Advantages of using spiral duct-work:

- It is strong and durable.

- It is lightweight.

- It is available in a variety of sizes and shapes.

- It is visually appealing.

- It requires minimal maintenance.

- It can be painted to match your decor.

Disadvantages of using spiral duct-work:

- It is not as flexible as other types of duct-work.

- It can be noisy in some high velocity applications.

- It is not as energy-efficient as some other types of duct-work.

- It can have have minor condensation issues.

Overall, spiral duct-work is a versatile and cost-effective material that can be used for a variety of applications. It is a good choice for many HVAC and ventilation systems.

Spiral Duct Systems

Spiral duct-work is a type of rigid duct-work that is made by winding a sheet of metal into a spiral shape and is found commonly in buildings with open ceilings. It is most commonly made of galvanized steel, but it can also be made of stainless steel, aluminum, or copper. Spiral duct-work is a versatile material that can be used for a variety of applications, including:

- Heating and cooling systems

- Ventilation systems

- Dust collection systems

- Fire protection systems

- Industrial applications

Spiral duct-work is available in a variety of sizes and shapes to meet the specific needs of each application. It is also relatively easy to install and maintain.

Advantages of using spiral duct-work:

- It is strong and durable.

- It is lightweight and easy to transport.

- It is a cost-effective option.

- It is available in a variety of sizes and shapes.

- It is visually appealing.

- It is easy to install and maintain.

- It is can be painted to match your decor.

Disadvantages of using spiral duct-work:

- It is not as flexible as other types of duct-work.

- It can be noisy in some applications.

- It is not as energy-efficient as some other types of duct-work.

- It can have have minor condensation issues.

Overall, spiral duct-work is a versatile and cost-effective material that can be used for a variety of applications. It is a good choice for many HVAC and ventilation systems.

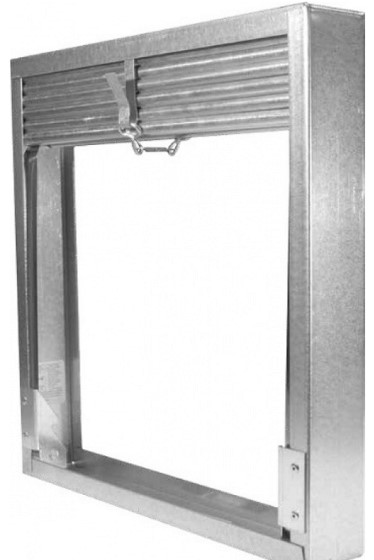

Fire Dampers

HVAC fire dampers are devices that are installed in duct-work to prevent the spread of fire. They are typically made of metal and have a closure mechanism that activates when it senses heat or smoke.

HVAC fire dampers are required in many buildings, including those that are classified as high-rise or high-occupancy. They are also required in buildings that are located in areas that are prone to wildfires.

The installation of HVAC fire dampers is a complex process that should only be done by a qualified professional. The dampers must be properly sized and installed to ensure that they function effectively.

Benefits of using HVAC fire dampers:

- They help to prevent the spread of fire, which can save lives and property.

- They can help to reduce the amount of smoke and fumes that are produced during a fire.

- They can help to improve the safety of occupants and firefighters.

If you have fire dampers installed in your duct-work system, Air & Electrical Services can provide the maintenance and inspection services you may need.

AHCA Inspections

Fire damper inspections are required to be performed regularly by some agencies to ensure that the dampers are in good working order and can function properly to prevent the spread of fire. The inspection should be performed by a qualified professional who is familiar with ASHRAE Standards.

An inspection from Air & Electrical Services includes the following:

- Visual inspection of the dampers to ensure that they are not damaged or obstructed.

- Operation of the dampers to verify that they close properly.

- Testing of the dampers to ensure that they meet the requirements of ASHRAE Standard 139-2020.

The inspection results are documented and include a report with the findings of the inspection. The report is often required by governing agencies such as AHCA to be kept on hand.

In general, fire dampers should be inspected every four years for non-hospital facilities and every six years for hospitals.

Here are some of the consequences of not having fire dampers inspected regularly:

- The dampers may not close properly in the event of a fire, which could allow the fire to spread.

- The dampers may not meet the requirements of the building code, which could make the building non-compliant.

- The dampers may be damaged or obstructed, which could prevent them from closing properly.

If you are responsible for the maintenance of fire dampers in a building, it is important to have them inspected regularly by a qualified professional like Air & Electrical Services. This will help to ensure that the dampers are in good working order and can function properly to prevent the spread of fire.

AHCA Inspections

Fire damper inspections are required to be performed regularly by some agencies to ensure that the dampers are in good working order and can function properly to prevent the spread of fire. The inspection should be performed by a qualified professional who is familiar with ASHRAE Standards.

An inspection from Air & Electrical Services includes the following:

- Visual inspection of the dampers to ensure that they are not damaged or obstructed.

- Operation of the dampers to verify that they close properly.

- Testing of the dampers to ensure that they meet the requirements of ASHRAE Standard 139-2020.

The inspection results are documented and include a report with the findings of the inspection. The report is often required by governing agencies such as AHCA to be kept on hand.

In general, fire dampers should be inspected every four years for non-hospital facilities and every six years for hospitals.

Here are some of the consequences of not having fire dampers inspected regularly:

- The dampers may not close properly in the event of a fire, which could allow the fire to spread.

- The dampers may not meet the requirements of the building code, which could make the building non-compliant.

- The dampers may be damaged or obstructed, which could prevent them from closing properly.

If you are responsible for the maintenance of fire dampers in a building, it is important to have them inspected regularly by a qualified professional like Air & Electrical Services. This will help to ensure that the dampers are in good working order and can function properly to prevent the spread of fire.

Fresh Air Duct Systems

Your fresh air system includes are all the components of an HVAC system that bring fresh air into a building.

HVAC fresh air systems can be beneficial for a number of reasons, including:

- Improved indoor air quality

- Reduced risk of mold and mildew growth

- Increased energy efficiency

- Improved comfort

If you are concerned about air quality, need repair, or have an issue with balancing, Air & Electrical Services can evaluate your system to locate any deficiencies and provide you with a corrective action plan. Contact us today for to schedule a consultation.

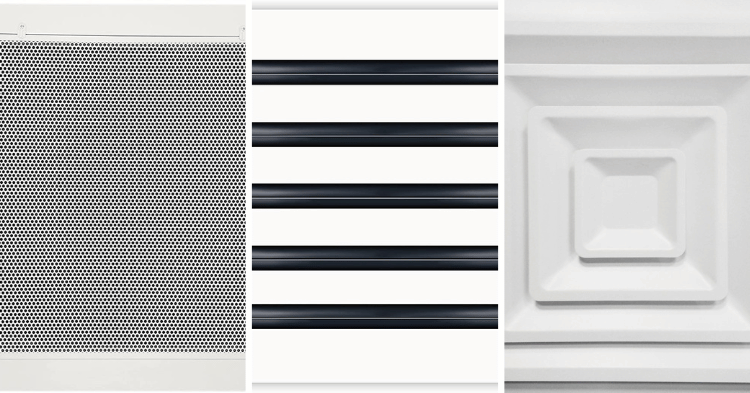

Register Options

There are hundreds of options for registers available in today’s market. The registers most often used in commercial applications are:

- Step down: found in a lay-in ceilings. These diffusers have multiple levels to disburse the air evenly.

- Perforated Lay-In: found in lay-in ceilings, these grilles have lots of small holes to disburse air, leaving a flat ceiling look.

- Linear Slot Diffusers: Found in custom buildings, these grilles often feature a long single linear opening to disburse air.

Register Options

There are hundreds of options for registers available in today’s market. The registers most often used in commercial applications are:

- Step down: found in a lay-in ceilings. These diffusers have multiple levels to disburse the air evenly.

- Perforated Lay-In: found in lay-in ceilings, these grilles have lots of small holes to disburse air, leaving a flat ceiling look.

- Linear Slot Diffusers: Found in custom buildings, these grilles often feature a long single linear opening to disburse air.